We at Engconsultproject Ltd. offer integrated solutions for road surveying.

The system consists of a special vehicle (Survey Van) and specialized software (Road Doctor Designer) purchased from the Finnish company Roadscenners Oy, the manufacturer and supplier of the system.

- CamLink system

- 2D Laser Scanner system

- Accelerometer

- Georadar

Specialized CamLink system

The Road Doctor CamLink system includes a high-quality GPS device, camcorders designed for high-speed video recording, and a dedicated laptop. All devices are quickly mounted on the roof of the vehicle in special sturdy plastic boxes that protect them from dust and rain. The system allows you to define up to 10 reporting parameters while recording a video file. The set parameters can be lengthy, such as trenches, cracks or patches, or short ones, such as drains and road signs. All possible 10 parameters can be categorized into up to 4 classes.

Specialized 2D Laser Scanner system

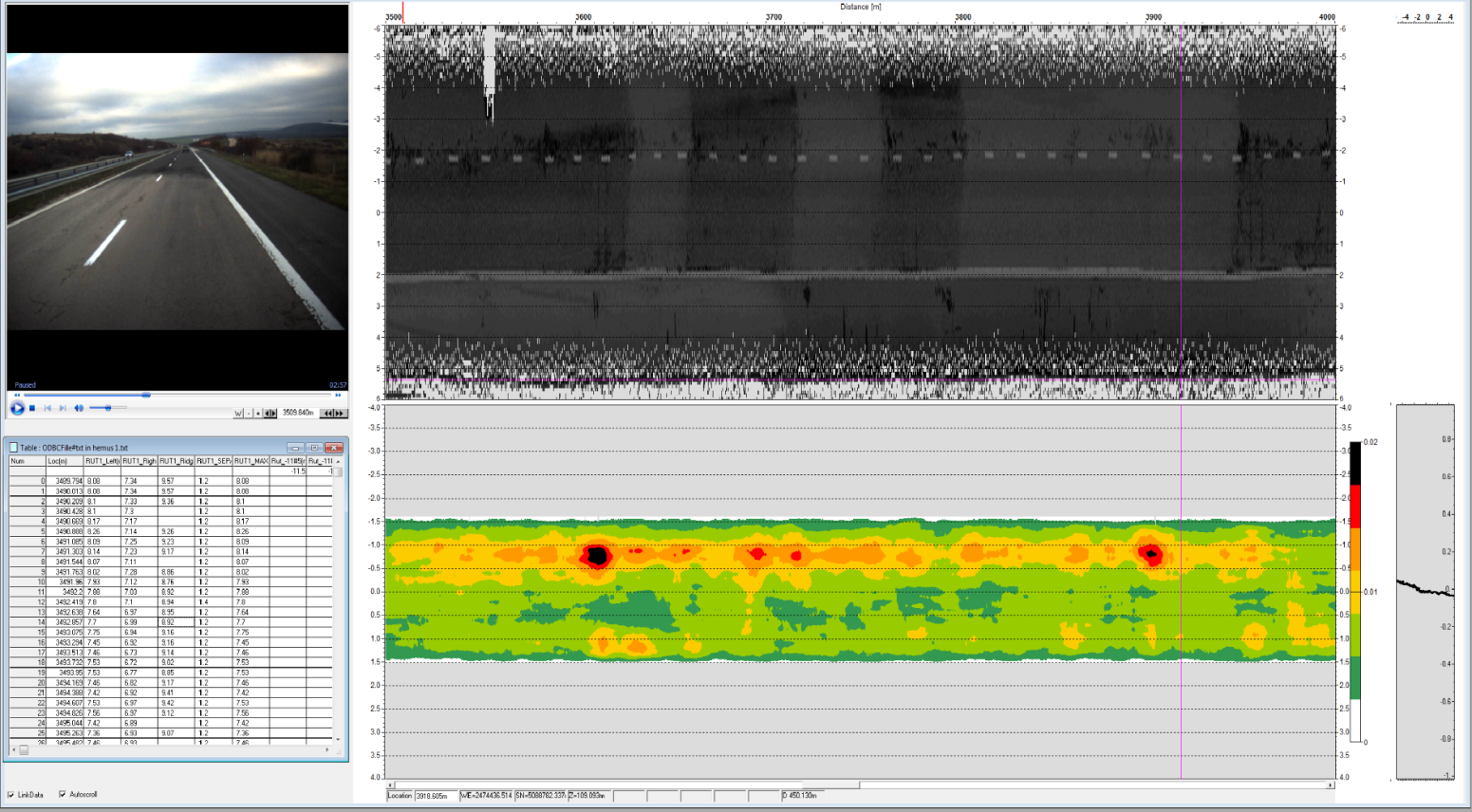

The Road Doctor 2D Laser Scanner system includes all elements of the Road Doctor CamLink system, an integrated laser scanner, and a 3D accelerometer. Laser scanning has various applications for roads. Cross-sectional road profiles provide information on the location, depth and type of track formed, the trenches and other road elements.

The final depth map shows the exact location of the deformation or wear of the pavement. The map, showing the levels of the road surface in different colors, is ideal for analyzing drainage and identifying areas with clogged trenches or clogged drains. Based on the data obtained from the laser scanner, changes in road widths and places with recently laid asphalt can be identified and measured.

Accelerometer

The accelerometer is used to study leveling. It collects data on the leveling of the pavement and existing transverse collapses of the roadway.

Specialized CamLink system

The Road Doctor CamLink system includes a high-quality GPS device, camcorders designed for high-speed video recording, and a dedicated laptop. All devices are quickly mounted on the roof of the vehicle in special sturdy plastic boxes that protect them from dust and rain. The system allows you to define up to 10 reporting parameters while recording a video file. The set parameters can be lengthy, such as trenches, cracks or patches, or short ones, such as drains and road signs. All possible 10 parameters can be categorized into up to 4 classes.

Road Doctor Designer

Road Doctor Designer software allows us to integrate and analyze data from a digital camera, a laser scanner, an accelerometer, and a radar.

By using built-in equipment and specialized software, we conduct a thorough road surveying, such as:

- the digital camera captures the condition of the road surface, including the horizontal and vertical road markings;

- the laser scanner allows to determine the road cross-sections and trenches, the width of the road and the pavement, the deformations on the lane (data on the length and depth of the formed tracks and data on the available transversal collapses);

- the accelerometer gives information about the leveling of the pavement;

- the radar determines the type and thickness of the pavement layers.

The advantage of using a specialized vehicle with the Road Doctor specialist equipment installed is that measurements can be made at a vehicle’s normal speed – up to 80 km/h.

Engconsultproject Ltd. has a specialized Deflectograph Lacroix car which is used to measure the elasticity of the road surface.

Deflectograph Lacroix of Vectra AD, France is a device for continuous automatic measurement of the elastic deformation of the road surface under a specified axle load. The possible load ranges from 5 to 13 t/axle. The measurement is carried out simultaneously for the wheel tracks of the particular lane. Deformation data are taken at intervals of about 6 months. The data obtained are used to analyze and evaluate the load-bearing capacity of the road surface and to determine the thickness of the reinforcement of the various layers of road surface required for road repair.

The device can measure the length of measured road sections and, therefore, all data relating to their actual location without the need for additional marking. The measurement results are recorded on a disk and then processed with appropriate software.

Description

Deflectograph Lacroix measures the vertical deformation (elasticity) of a surface under the influence of heavy loads moving at a constant speed.

How it works

The elasticity is measured between the wheels on the rear axle of the vehicle via a beam with sensors through which the measurements are made. This beam moves independently of the vehicle on which it is mounted, touching the road surface at three points outside the zone of weight impact. Static elasticity data (obtained by sensors placed on the road surface) is very well determined even with slight deformation of the road surface.

Specifications

The device consists of the following elements:

- a truck with two axles and a wheelbase of about 5 m; the rear axle must be able to carry a load of 13 tonnes.

- a beam equipped with two arms with sensors

- electronically controlled pull-out and leading mechanism to prevent the ends of the beam from being crushed.

- control console for electronic measurements and recording equipment.

- weights fixed at the back of the truck.

Characteristics

- The vehicle speed during measurements is 3 km/h ± 0,5 km/h.

- The distance between the measuring intervals is 3 to 6 meters, depending on the vehicle used and the testing speed.

Application

Deflectograph Lacroix is mainly used in:

- Monitoring of the road network as well as the change in its condition under the influence of traffic.

- Identification of weak areas that need to be rehabilitated or reconstructed.

- Monitoring of the performance and the effectiveness of pavement reinforcement.